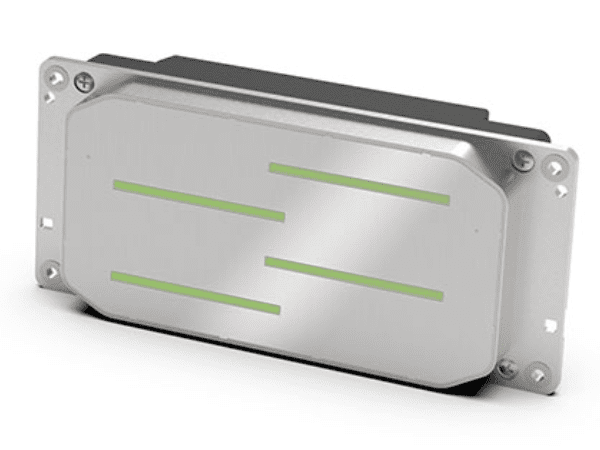

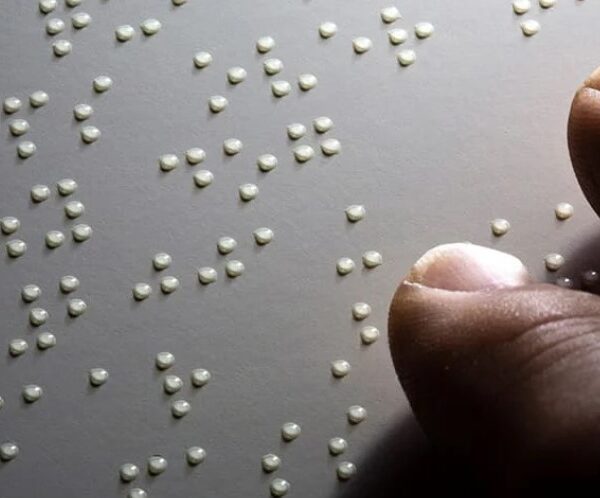

Xaar evidentiaza modul in care tehnologia inkjet poate crea elemente tactile Braille

Recent, compania britanica Xaar a publicat un nou document tehnic in care prezinta modul in care Versatex, noul sau modul liniar de imprimare, poate fi integrat pe echipamentele de print analog pentru a crea elemente decorative pe ambalaje in Braille. Versatex ofera doua moduri dedicate pentru imprimarea Braille — modul High-Build si modul High-Speed